Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() June 25, 2021

June 25, 2021

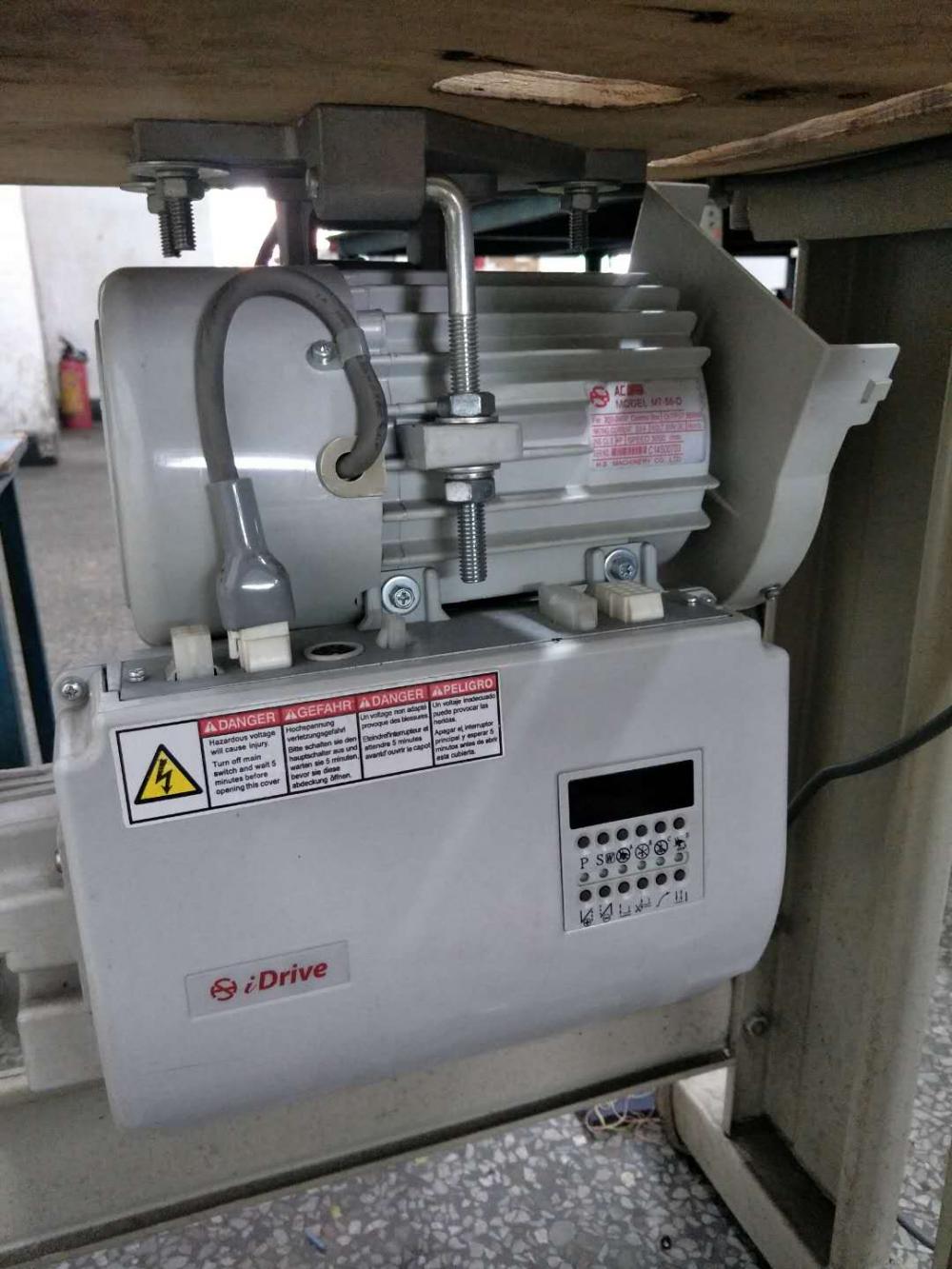

Through the correct operation and maintenance of the servo system, restore the normal operation of the equipment, what are the methods to detect the faults of the servo system of the Industrial Sewing Machine?

Method 1: observation

Observation method is the most basic maintenance and inspection method. It mainly refers to that maintenance technicians rely on vision and touch, through careful observation of the machine, and then compare with the normal working state of the system, so as to narrow the fault scope or directly find the fault location. For example, observe whether the controller and display screen are scratched, whether the plug is disconnected, whether the lead is disconnected, whether the circuit board components are scorched, whether the pins are broken, and whether the pins are collided.

Method 2: system automatic detection method

Today's industrial sewing electrical control system generally has the function of intelligent automatic fault detection. According to the different alarm codes of the system, we can judge which faults have occurred in the system, and then judge which part has problems.

After determining the fault code, the corresponding treatment method can be used to repair. Different brands of electronic control systems may use different fault codes, but the specific fault types are not different. In addition, the manual of the electronic control system is also marked with obvious and specific notes.

Method 3: substitution

Replacement method is the most effective repair and inspection method to reduce the scope of failure, that is, to replace the corresponding parts on the equipment with new parts, so as to determine whether the parts are faulty, faulty parts or faulty specific components. When repairing, we should start with the large parts and gradually replace them until we find the fault. This method is mainly used when the accessories are sufficient or the electronic control system is in good condition.

For example, in the maintenance of AC servo system, it must be determined whether it is a system problem. Generally, the method of replacing the normal control box is used to judge whether the fault is the mechanical problem of the industrial sewing machine or the problem of the control box. This method is also used to repair circuit boards. Replace the "suspicious" fault component in the circuit with a good one, observe the change of the controller, and judge the fault.

Method 4: open circuit test

Open circuit inspection method is to disconnect a functional circuit in the control system, observe the working state of the control system, and narrow the fault range. For example, if the electromagnet function of the electronic control system fails, the alarm can be given by disconnecting the electromagnet connector or further disconnecting the power supply voltage of the electromagnet to determine whether there is a fault in other circuits.

Method 5: voltage measurement

When the AC servo controller works normally, the working voltage of each point in the machine indicates the working state of the machine within a certain range. When the fault occurs, the working voltage must change. The method of voltage measurement is to use a multimeter to detect whether the working voltage of each connector and each test point of the circuit board is too large or too small, and judge the specific cause of the fault according to the abnormal voltage. When measuring, pay attention to the different gears of the multimeter, and measure the AC voltage and DC voltage.

Voltage measurement method is usually carried out when the machine is electrified, so attention should be paid to one hand operation and safety first. For example, when the electronic control system does not respond after starting, it needs to measure from the switch to the circuit board one by one when the power is on until the open node is found.

Method 6: resistance measurement

The resistance measurement method is to detect the on-off and resistance value of the circuit through the ohm gear of the multimeter to determine the specific cause of the fault. When the working controller is not powered on, some lines are paths, some lines are open, and some lines have a certain resistance value. When it can't work normally, its resistance state changes. The resistance measurement method is used to detect these changes, and the fault location is determined according to these changes.

Remember to measure resistance, usually when the controller is not charging. For example, the fault detection of the electromagnet is to measure the resistance of the multimeter through the ohm file of the multimeter to judge whether the electromagnet is working normally.

The above is the How to Dectect Servo System Failure Of Industrial Sewing Machine we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Send Inquiry

Mr. Alston Chen

Tel:86-769-18902616250

Fax:86-769-88285668

Mobile Phone:+8618902616250

Email:sales02@chuanghuisew.com

Address:26-28 Zhenglu south, chuancha village, Machong Town, Dongguan City, Guangdong Province., Dongguan, Guangdong

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.